Inside the Clearaudio factory: building £145,000 turntables and assembling cartridges by hand

Made (mostly) in-house since 1978

The latest hi-fi, home cinema and tech news, reviews, buying advice and deals, direct to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Established German company Clearaudio has been producing audio products and components since 1978. In that time, it has probably forged the strongest aspect of its reputation as a purveyor of turntables and cartridges, many of which are targeted at the high-end and luxury consumer markets, but it was a duo of loudspeakers – the Delta and Sigma standmounts – which marked the brand's official debut.

From its surprisingly bucolic factory situated on the edge of Erlangen, a Bavarian city around 30 minutes north of Nuremberg, Clearaudio continues to produce a raft of audio products in-house, with almost all areas of research, design, development and production happening from the site itself.

There's nothing quite like a turntable to scratch that strange analogue itch found deep within every audiophile and lover of physical design. From first stages to final assembly, this is how Clearaudio gets your vinyl spinning.

A clear vision

We'd start right now by saying that we're no suckers for marketing blarney. We'd also say that, as far as tour guides go, you couldn't find many more engaging, affable and passionate than CEO Robert Suchy who, alongside his sister and the brand's COO Veronika, is one of the driving forces behind Clearaudio.

There's also a very handsome and affable golden retriever called Baxter who roams the company halls receiving adoring scratches, a feature which should be mandatory in offices across the globe.

"Take the best, make it better – only then is it good enough." That's the slogan you'll find taking pride of place on Clearaudio's impressively enticing website, a statement which the members of the team to which it belongs seem to adhere to diligently.

Again, Robert's story that his greatest challenge often lies in telling his team of engineers and developers when to stop engineering and developing a product so that it can actually go to market sounds superficially self-aggrandising, but given the passion and precision on display, it's hard not to be pulled in.

The latest hi-fi, home cinema and tech news, reviews, buying advice and deals, direct to your inbox.

And it really is Clearaudio who are doing the taking and the making. As part of its commitment to quality and independence, the vast majority of the brand's components and produced in-house at the Erlangen factory.

The company also collaborates with external researchers and suppliers when necessary, filling in the gaps that in-house development or research can't quite fill; though. as Robert tells us, having a large university nearby and multiple cities with deep roots in manufacturing never hurts when you're trying to find great people to do great work.

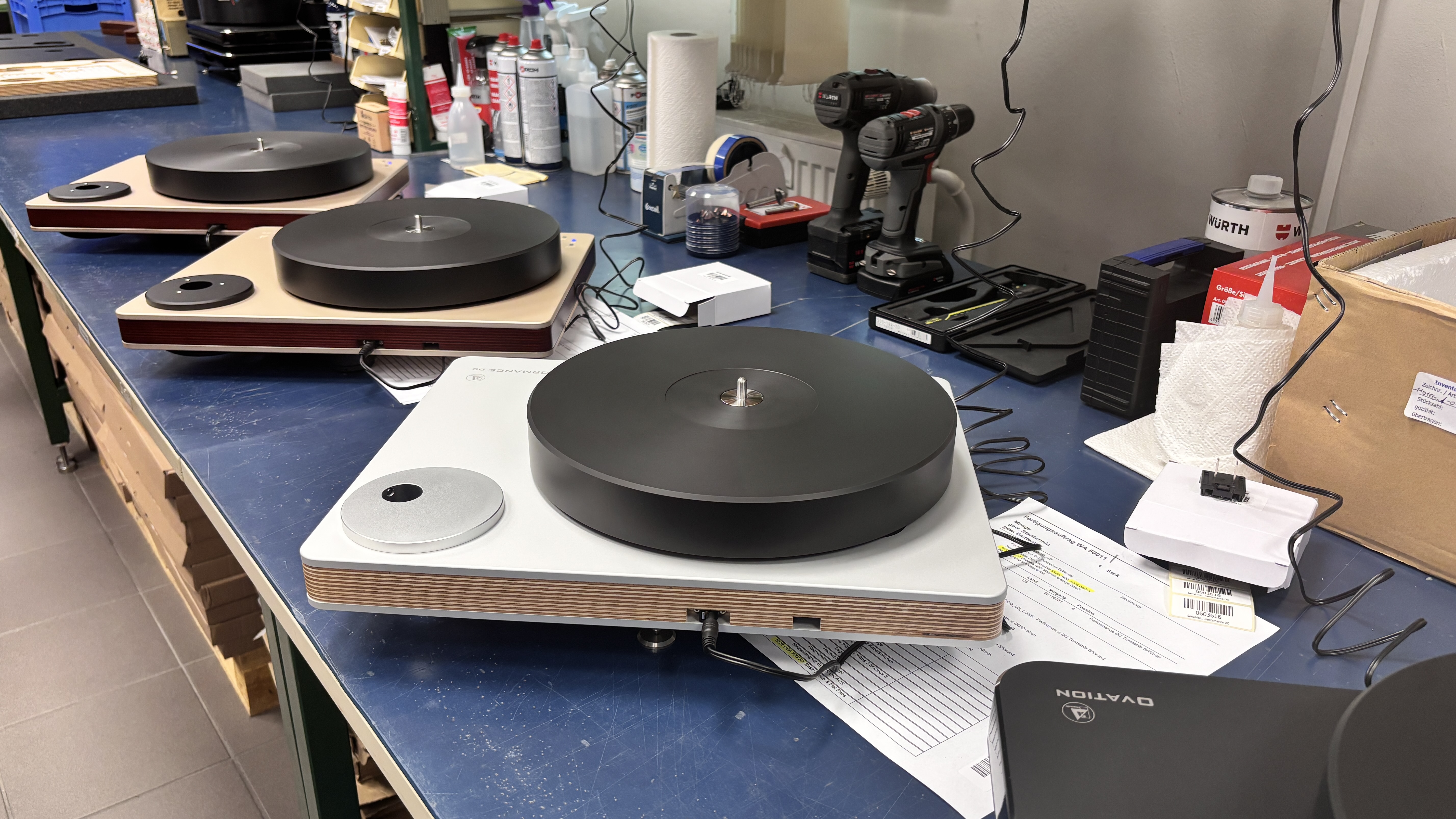

Putting it all together

As stated above, Clearaudio makes almost all of its components in-house which, in an age of Chinese super factories firing out bespoke elements at budget prices within days or even hours of a request, is a remarkable thing in its own right.

Move through the Erlangen facility and, from room to room, you'll discover stations dedicated to each phase of production required to take a random assemblage of materials into a multi-thousand-pound spinner. From the body to the tonearms to the cartridges, it's all here, just waiting to be put together and assembled into the finished item.

It's a modular affair, with almost every room (none of which are particularly capacious in size) dedicated to a different element of assembly. In one area you'll find CNC machines responsible for precisely marking out metallic panels, while in others you'll discover the high-torque DC motor, exclusive to Clearaudio, which goes into driving the stunning-looking Master Innovation deck.

Despite the presence of a few key machines, it's a remarkably human process. One of the lighter, airier rooms near the back of the facility houses three or four workers who are busy assembling a range of tonearms by hand; another, as we'll see, is dedicated to the small but mighty cartridges on which Clearaudio has built much of its current reputation, while another department handles servicing and repairs for faulty or damaged goods.

There are, as you might have imagined, a lot of elements that go into making even the most basic turntable in the company's range. The Reference Jubilee, for instance, uses multi-layered and laminated wood for the bulk of the unit's chassis, whereas the platter of the Innovation deck uses ceramic magnetic bearings and a synthetic platter chosen for its greater density and outstanding stability.

Again, these are elements which have been through the entire process of production, from conception to 3D printing to final production, at the Clearaudio factory – take a tour for yourself and you'll be able to pick up a spare motor or the aforementioned multi-layered wooden chassis deployed in many of the company's high-end decks.

Gold standard cartridges

If you thought the process of making a turntable was tricky, it's nothing compared with the intricacy and skill involved in putting together the perfect cartridge. As is the case with its decks, Clearaudio assembles its cartridges predominantly by hand, a process that involves some striking levels of human skill.

While not every cartridge the German brand produces reaches the lavish levels of luxury exhibited by the £22,000 Diamond Jubilee, high-end products – and therefore materials – are the order of the day. Clearaudio produces some of the smallest and lightest coils in the world, for instance, prized for their lightness and flexibility in pursuit of a more precise audio signature.

Take the gold wire that needs to be wrapped around the cartridge currently in production during our demo. Working under a high-powered Japanese microscope that magnifies the coil to up to 200 times as it is attached to the body by hand, it's a precise process that puts one in mind of a bomb diffuser trying not to cut the wrong wire.

Processes such as these are too delicate for machines to handle, and it's here that human employees, some of whom undergo months of training, remain vital in this post-industrial world.

On a good day, we're told, you might be able to get two or three cartridges finished if your brain is properly in gear. If you're tired, hungover or just not feeling it, you might struggle to manage a single one.

Future plans

We're reassured to hear that the Clearaudio team are passionate about music, and it's through innovation and research that they hope, primarily, to bring out the best that a record has to offer. As seems to be a common theme whenever we talk to manufacturers and enthusiasts, these are products designed with your music in mind.

That enthusiasm comes across most openly when a small group of the attending press are given the chance to hear what one of the brand's most luxurious decks, the Statement, has to offer when charged with firing out The Curse by Agnes Obel followed by some European jazz and then Quincy Jones' Coming Home Baby. As we listen to the impressive setup (a pair of Audio Physic Cardeas speakers never hurts), it's clear that Robert derives as much pleasure from hearing his products as we do, and that the thrill remains fresh after all these years.

They're also made with one eye on customers' needs, and in fairness to Clearaudio the brand seems to maintain a strong bond between itself and the end user. One particular story stands out of a man who, at all times, required two high-end, multi-thousand-pound cartridges to be in his home at all times: one for use, and one as a backup in case the first one broke and needed to be sent in for repairs. When your most expensive cartridge flies north of £20,000, that's some brand loyalty.

Whatever the case, the idea of a high-end manufacturer of turntables isn't as anachronistic as it may have first appeared. Independent ownership and self-sufficiency remain notable, but with vinyl's resurgence continuing apace, turntable production itself doesn't look like it's set to be consigned to the history books.

If anything, the young, entry-level consumers of today may, a few years down the line, be the big-money spenders of tomorrow. For Clearaudio, that will be no bad thing.

MORE:

The 11 most exciting hi-fi products we saw at High End Munich 2025

These are the best turntables we've tested

And the best cartridges, too

Harry McKerrell is a senior staff writer at What Hi-Fi?. During his time at the publication, he has written countless news stories alongside features, advice and reviews of products ranging from floorstanding speakers and music streamers to over-ear headphones, wireless earbuds and portable DACs. He has covered launches from hi-fi and consumer tech brands, and major industry events including IFA, High End Munich and, of course, the Bristol Hi-Fi Show. When not at work he can be found playing hockey, practising the piano or trying to pet strangers' dogs.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.