Inside the Sennheiser factory: assembling audiophile headphones and listening to £60k electrostatics

“Audiophile assembly is not easy”

The latest hi-fi, home cinema and tech news, reviews, buying advice and deals, direct to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Is there a brand more synonymous with headphones than Sennheiser? Sure, there are plenty of brands such as Bose, Sony, Grado, Stax and more that have many corners of the headphone market sewn up. But none is more prevalent and renowned throughout the world – and across decades – than Sennheiser’s range of wired headphones.

From its HD 414 on-ears with the distinctive yellow earpads from 1968 to the hugely accomplished HD 600 range (which is featured in What Hi-Fi?’s best headphones of the 21st century list and in our best hi-fi products of the 1990s), the German brand has staked its claim as a pioneer and pinnacle of headphone performance.

What you might not know is that Ireland plays a huge part in its well-regarded audiophile headphones ranges. Since 1991, Sennheiser’s factory in Tullamore, Ireland (about an hour’s drive from Dublin) has been the main facility for manufacturing the high-quality transducers found in the brand’s audiophile headphones, including those in the famed HD 600 range for the past two decades. It was only recently, in 2022, that the assembly of these headphones was also ported into this same Tullamore factory. Sennheiser says this “improves transducer matching”, and being able to assemble the headphones and get them ready for the final packaging in the same place guarantees that quality control standards are met throughout for the customer.

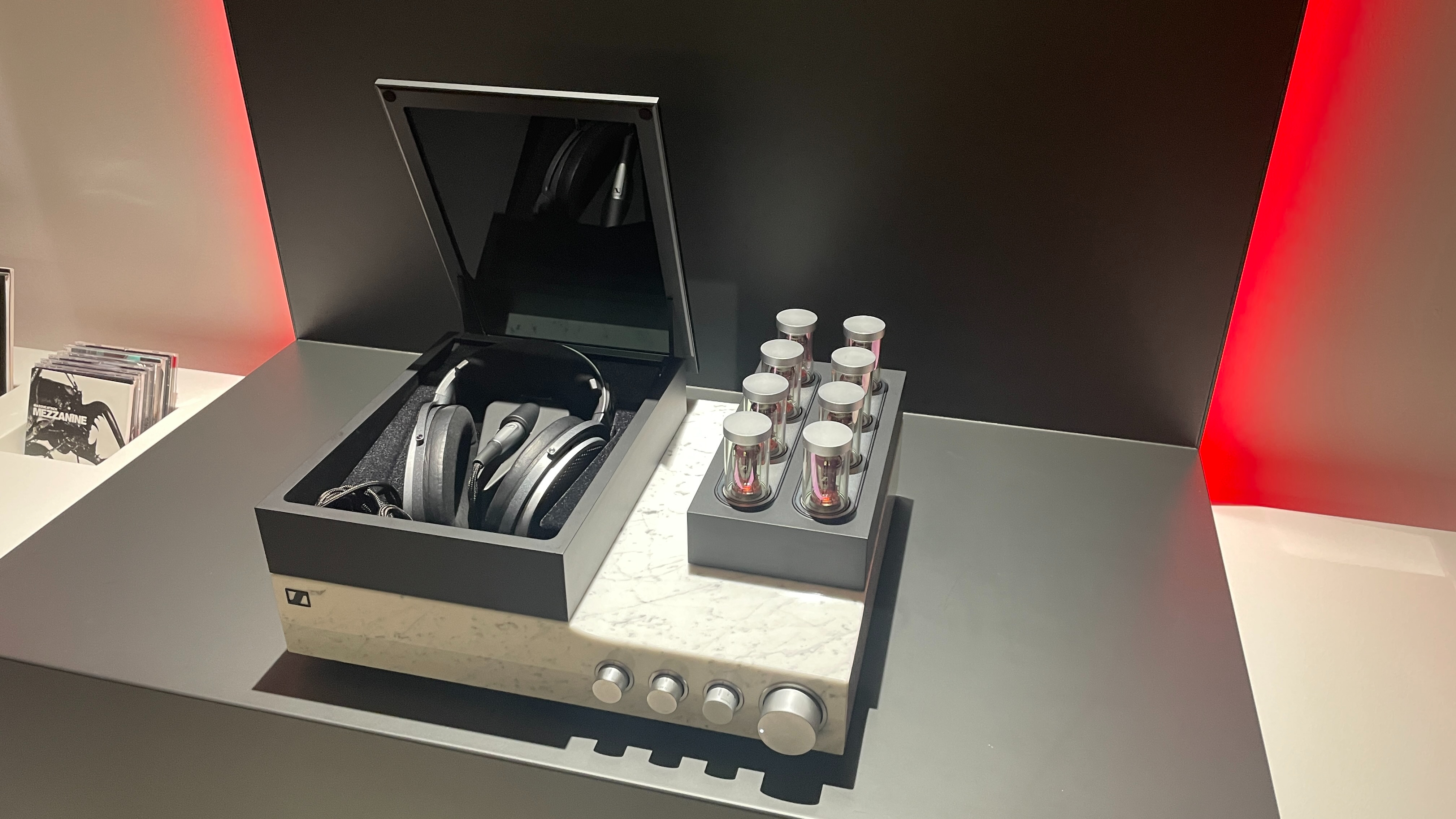

The Tullamore plant is also the place where they assemble Sennheiser’s flagship HE 1 (nicknamed “Orpheus” at its 2015 launch) electrostatic headphones, which cost between £55,000 to £60,000 these days. You might have seen this astonishingly priced product on many a “most expensive headphones ever” list, such as our own.

Tullamore, then, is where the heart of Sennheiser’s audiophile headphones lies. The factory has evolved over time and has been spruced up even more recently to include a new hi-fi listening room where visitors can sit comfortably and listen to these HE 1 headphones or any of Sennheiser’s other wired headphones that they make just a few feet away.

Automated transducer manufacturing

What’s striking about the Tullamore factory is the combination of automated processes in place and the very manual, very human expertise needed for making Sennheiser’s wired headphones. Rows of very clever, very precise machines are dedicated to making the transducers, ranging from extremely tiny ones used in the in-ear IE 600 and IE 900 models, to the larger drivers used in the HD820, HD800S, HD600, HD650 over-ear cans.

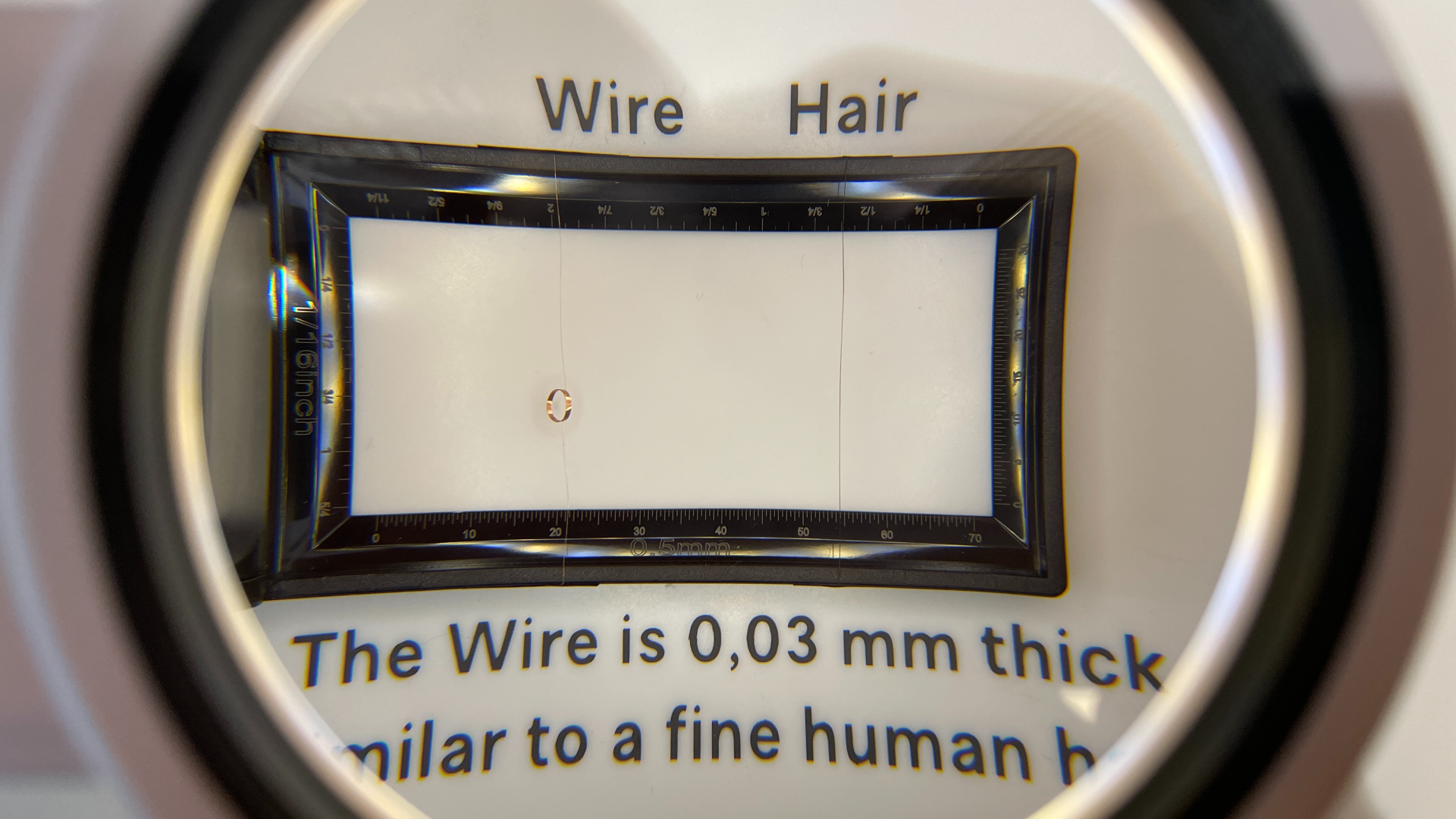

There are about a dozen machines doing roughly 70 different processes at any one time. There’s a machine that winds the very fine coil wire (some 0.03mm thin, similar to fine human hair) a specific amount of times for the best performance; there’s one that applies the special pink glue that holds the transducer casing together. A machine that uses a ‘plasma nozzle’ to bind the electrical wires to the transducer to create the signal path sits alongside one that flashes a light that detects any minute errors in the process so far. In between each step, there are machines that check and test that every element is being perfectly made (with human experts on standby, too, of course).

The latest hi-fi, home cinema and tech news, reviews, buying advice and deals, direct to your inbox.

Pat Fulton, the Sennheiser Tullamore plant manager and our guide, says that each machine has been made specifically to Sennheiser’s needs, and so are one of a kind. There is a steady whizz and whirr on the factory floor; the automated machines are abuzz, but they are also neat and orderly. There is a clear flow in the machinery process that’s fascinating to see, especially seeing the transducers being shipped along conveyor belts between the machines.

I’m told that the system is flexible enough to allow for changes to be made. Whether that’s a different transducer or headphone model that needs priority in the manufacturing process or any maintenance or changes to the machinery itself – even if one machine stops, it doesn’t necessarily slow the production flow. Fulton says there’s always another model or another element of the process that can be tagged in so that production doesn’t ground to a halt.

There isn't a set amount of products having to be made, either; it all depends on the various different models and their cycle times in terms of assembly, production and demand. "There isn't a general rule of thumb," says Fulton, as the set up is "scalable for whatever we need to do" and "it gives us the flexibility to change around our production if we want to, which helps us to adapt to different requirements."

The human touch

Of course, not everything can be automated. As much as Sennheiser is proud of its very clever, very precise automated machines that make the transducers, there are some things that simply need the human touch.

“Audiophile assembly is not easy”, says Fulton. “It takes a lot of time and requires extreme precision and attention to detail as well as a lot of human interaction and passion.”

Various elements of headphones – the soldering, inserting the innovative glass reflector in the HD 820 closed-backs, the final assembly and checks – are done by a team of experts who have been trained in the art of this precise craft.

Fulton says that over his 30 years at the Tullamore plant, he has noticed that “Sennheiser as a brand has always pushed the boundaries to keep going and keep developing. And, you know, that's very good from a customer perspective. But for someone who works here, it also creates a constant energy and a challenge, which is great, and it's a constant learning."

A lot of the people who came to work at the Tullamore plant have also become more skilled and grown into more technical roles. “We constantly encourage that, because that's the secret of renewing everything and keeping your skill sets fresh and valid.” It also creates a level of passion, care and pride in making the headphones "that translates into the products and, you know, it only can be good.

“We’ve automated a certain level of transducer production, but once you get into the 800 realm and some of the HD 600 series as well, a lot of that is also manually made. There are a lot of good reasons for that – there is a skill and a craft in doing it. There’s quite a lot of skill and dedication and that attention to detail that’s required, that the products deserve themselves.

“We feel having that human interaction is very important. Like there are always elements that you will look to automate and to make more efficient… but there are certain things which just lend themselves better to that personal touch, really.”

Assembling a pair of headphones

Sennheiser isn’t about to let some journalist run loose with a soldering iron to its £2000 headphones (and rightly so), so the team has sensibly ushered me into the final assembly area for some hands-on experience.

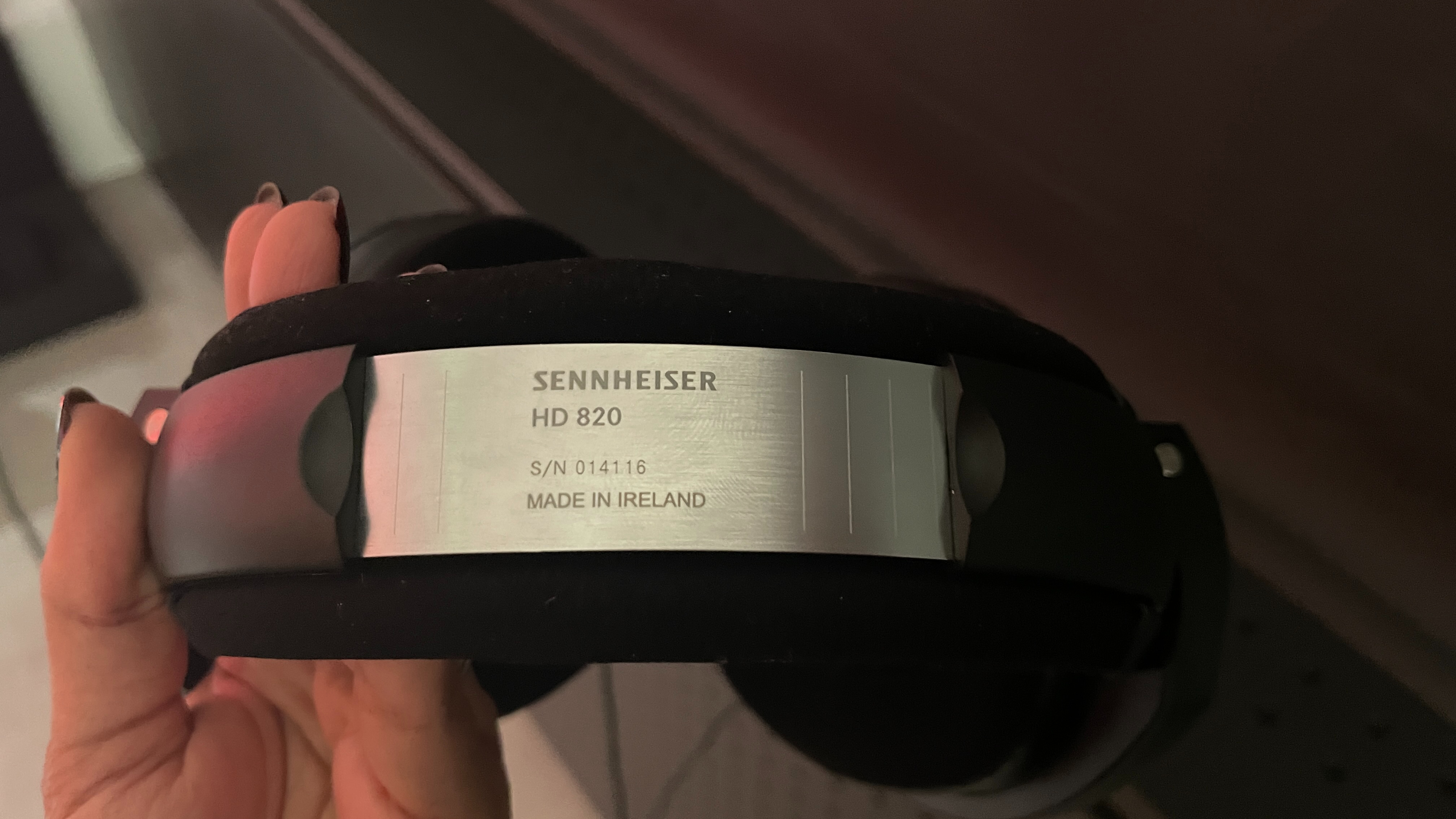

A big part of the non-automated section of the plant involves the assembly of the headphones themselves – it’s an element ported over from the Germany HQ and into the Tullamore factory. It means the headphones assembled here can carry the “Made In Ireland” badge on the headband, too.

I’m shown to a section where the HD 820/800S and the HD 650/660S2 headphones are assembled. On the day, it was the HD 600 model they had on the line. After watching the experts at work to see how it’s done, I got stuck in. Everything is laid out in an orderly fashion and it doesn’t take long to realise repetition breeds perfection; it isn’t as easy as it first looks, either. First, you have to snap in the outer frame to the two earcups, add in a layer of foam and attach the mesh grille, clip in the cushioned ear pads correctly (which takes more tries than I’d care to admit) and check for any marks or imperfections on the headphone itself or on the grille. Next, the headband needs clipping on and this takes proper grunt to ensure they align up perfectly with the slots in each earcup and are connected securely. Attaching the cables is far easier (the one marked red is for the right ear cup) and after one final test in a machine, I get to pack up the final assembled headphones into their cardboard box (this is, for me, the easiest bit to assemble), all ready for their new owner.

It may sound simple, but there are moments in each step that can trip you up. Ensuring the cables go in the right order and that the headband is oriented correctly are two key elements. How do you know? The ‘r’ in the Sennheiser logo on the headband points to the right earcup and cable – so there’s never any error or confusion on which way it should go. “Do you ever miss a step?” No, say the four women working in shifts in the assembly section; the headphones just feel wrong if it’s not done right, they say. You end up hearing or feeling for the way the parts all line up or snap together, they say, more than just looking at how the headphones are made. It’s a very tactile process, and one that does make you appreciate the work going into making these premium headphones.

Listening to the flagship HE 1 headphone system

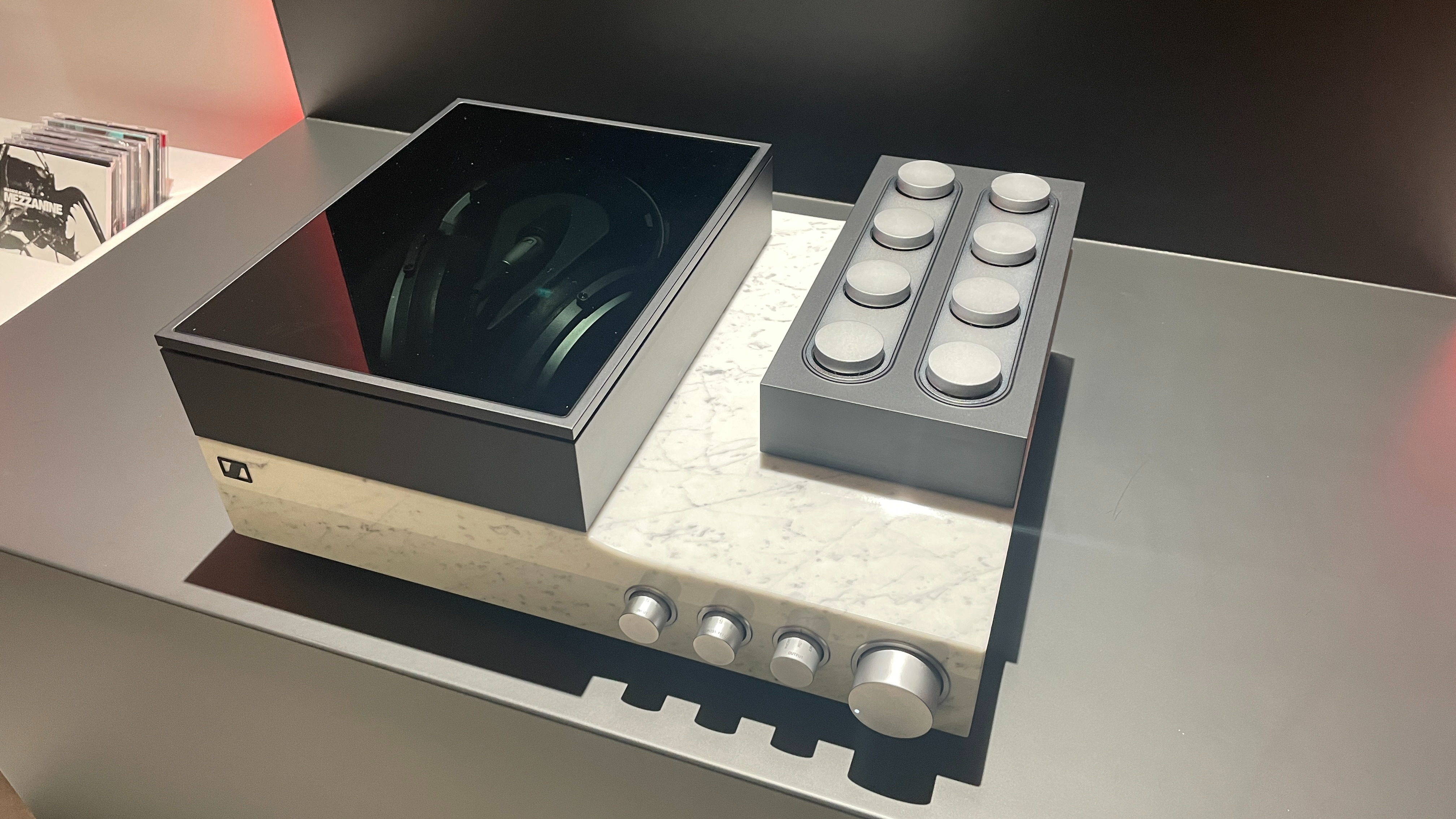

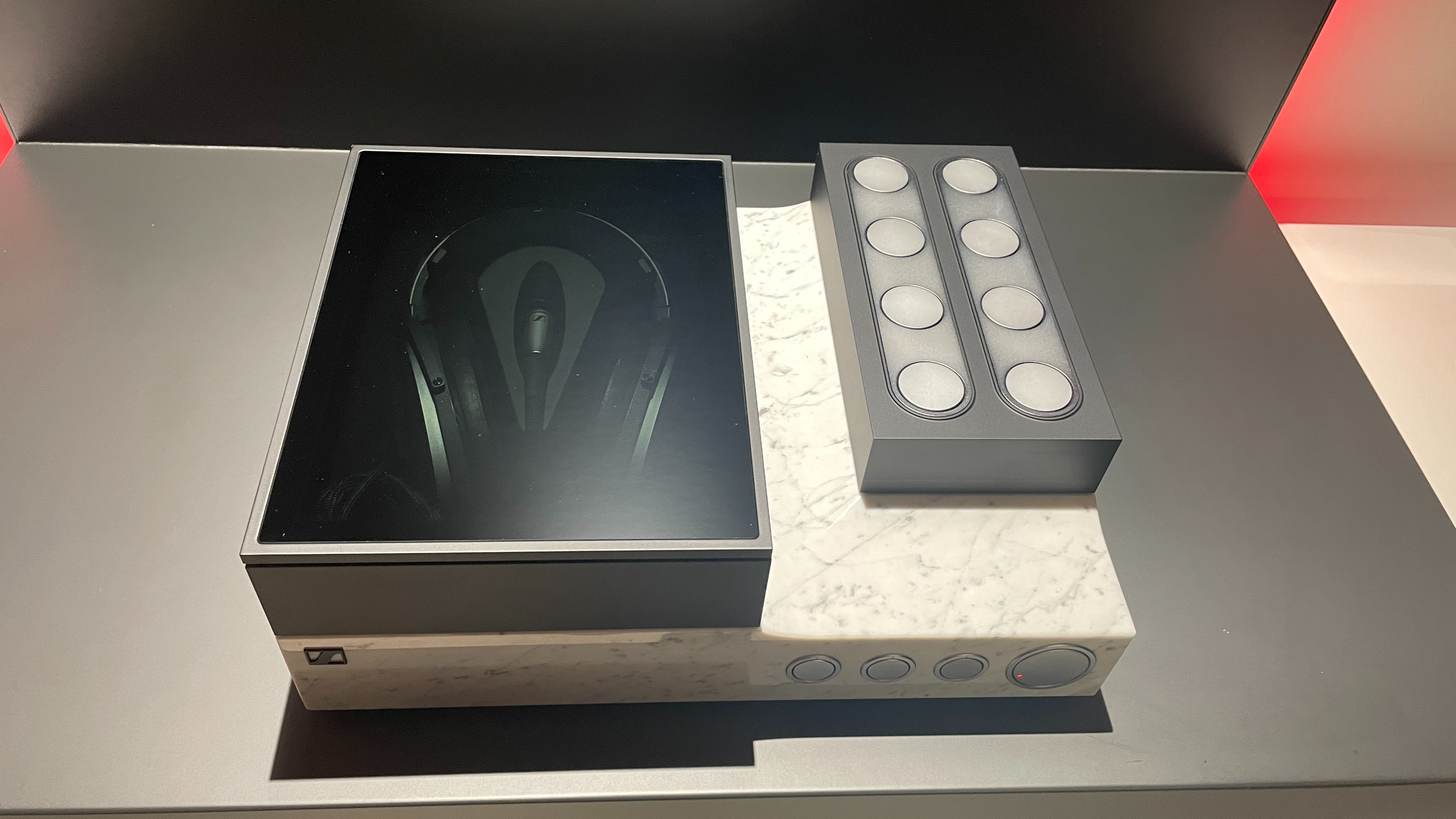

There is one space on the factory floor, sectioned off behind a large glass wall, that is dedicated to making just one headphone model: the HE 1.

It takes roughly two weeks to make just one HE 1 headphone system from start to finish. Some of the materials – such as the Italian marble housing for the valves and controls – need to be flown in, and any hiccups in this supply flow can delay the assembling process. That’s even before we take into account the amount of care, precision and testing that needs to be done to make such a technically advanced and incredibly expensive pair of headphones. Naturally, they are made to order.

In the separate listening room, you can listen to the HE 1 for yourself. The headphones are hooked up to two sources: the Rega Planar 3 turntable for spinning vinyl and Rotel’s Tribute CD11 player for playing CDs. You can peruse a selection of vinyl records and CDs (the same duplicated in both formats so you can listen to differences) featuring classic test album staples from Massive Attack, Pink Floyd, Daft Punk, Dr Dre and Miles Davis.

How does it sound? Quite unlike anything else. The open-back, electrostatic design affords it the kind of open, clean and refined performance like no other. Distortion levels are at an all-time low; I didn’t even realise just how loud I was listening to the Wish You Were Here album until I took the rather large headphones off. They are comfortable to wear too, despite the engulfing earpads.

The incredibly airy, spacious presentation offers more than ample space for instruments and voices to breathe; there’s depth and dynamics, with a level of sublime clarity and detailed, layered texture that lets you get fully immersed in the performance. You certainly don’t need any spatial audio gimmick here.

That airy, spacious presentation means so much room for instruments and musical elements to flow. Depth and dynamics, clarity and detailed texture that lets you sink into the music... I did end up preferring the vinyl version, but that could be down to the differences between the two source products used rather than the format.

The presentation of the HE 1 is what makes it really special, though, and makes it worthy of its high asking price. Calling it ‘high-end’ just doesn’t feel enough. As we detailed in our original hands-on experience when the HE 1 Orpheus was first unveiled in 2015, there’s a majestic elegance to the way the control dials and glowing valves emerge out from the marble casing, and the enticing way the smoked glass lid opens to reveal the headphones within. It’s mesmerising.

Check out the gallery below for more images.

Of course, it helps that the headphones sound so good as well. If you can afford a pair for yourself, colour us green with envy. You can also opt to listen to the more real-world priced (but still fairly premium) headphones, such as the HD 820, HD 650 or IE 900 – in this system instead of the HE 1.

There’s a pleasing harmony to being able to hold and hear these headphones – ones made just a few feet away – in a system and listen to what they are capable of. We are lucky enough to get a glimpse into how hi-fi products are made in these factory visits, but it’s quite something else to be able to have such a tactile experience and listen to the final product so close to where they are actually made.

MORE:

Read our original, full first impression of the Sennheiser Orpheus HE 1 headphones

And our more recent Sennheiser HD 660S2 review

The ultimate music tracks to test your hi-fi system

HUNTKLVJG

Kashfia is the Hi-Fi and Audio Editor of What Hi-Fi? and first joined the brand 13 years ago. During her time in the consumer tech industry, she has reviewed hundreds of products (including speakers, amplifiers, turntables and headphones), been to countless trade shows across the world and fallen in love with hi-fi kit much bigger than her. In her spare time, Kash can be found tending to an ever-growing houseplant collection and shooing her cat away from spinning records.